Steel blast furnaces powered by hydrogen would contribute significantly to a reduction in carbon emissions. This development is considered a Technology Landmark for an Omegamap.

The information presented below is based on an article; “How to Power a Steel Blast Furnace Using Only Hydrogen” written by Carolene Delbert on November 15 2019, in the Popular Mechanics Newsletter. This was based on an article published in Renew Economy written by Michael Mazengrab on November 13 2019. It was brought to our attention by Alan Brent in a post on LinkedIn.

Steelmakers in Germany moved toward carbon neutral steel production by using hydrogen to power a blast furnace. The company, ThyssenKrupp at its facility in North-Rhine Westphalia, used a new principle of operation. In its “furnace 9” it fed hydrogen into one of 28 tuyeres, or nozzles, that otherwise supply coal into the blast furnace. Following the successful trial, ThyssenKrupp plans to scale up the injection to all 28 tuyeres within the furnace and aims to eventually run at least three furnaces completely on hydrogen by 2023. It has committed to reducing emissions by 30 percent by 2030.

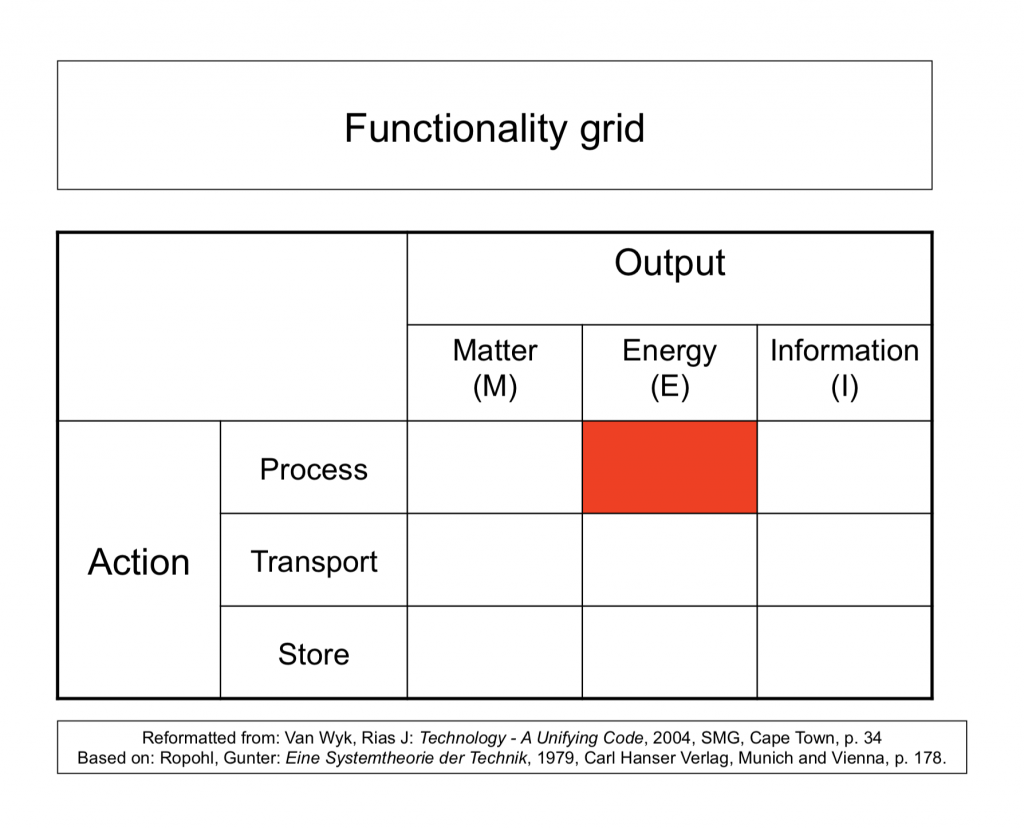

The functionality focused on here is Process-Energy. It is illustrated in the Functionality Grid below. To make 1000 kilograms of steel requires 780 kilograms of coal. Data could not be found on the input requirements of hydrogen. It is therefore not possible to calculate Functional Performance Metrics. However the company aims to be carbon neutral by 2050.

The technology readiness of this innovation is judged to be TRL 5 on a scale of 1 to 9, i.e. “Technology validated in relevant environment”.

Technical terminology is covered in: Van Wyk, Rias, (2017) Technology: Its Fundamental Nature, Beau Bassin, Mauritius, LAP LAMBERT Academic Publishing, (http://amzn.to/2Avsk3r)

For descriptions of:

- Technology Landmark; pp. 83-84, Diagram 11.1, Stage 3

- Principle of operation; p. 20

- Functionality; pp. 24-25

- OmegaMap; pp. 92-93

- Functionality Grid; pp. 29-32

- Technology readiness levels; pp. 22-23